Category: PrintingTips

MMU Test Print

Here is a simple print and concept that should be in every MMU owners toolbox. Small Prints quickly Changes tools often It is an ideal…

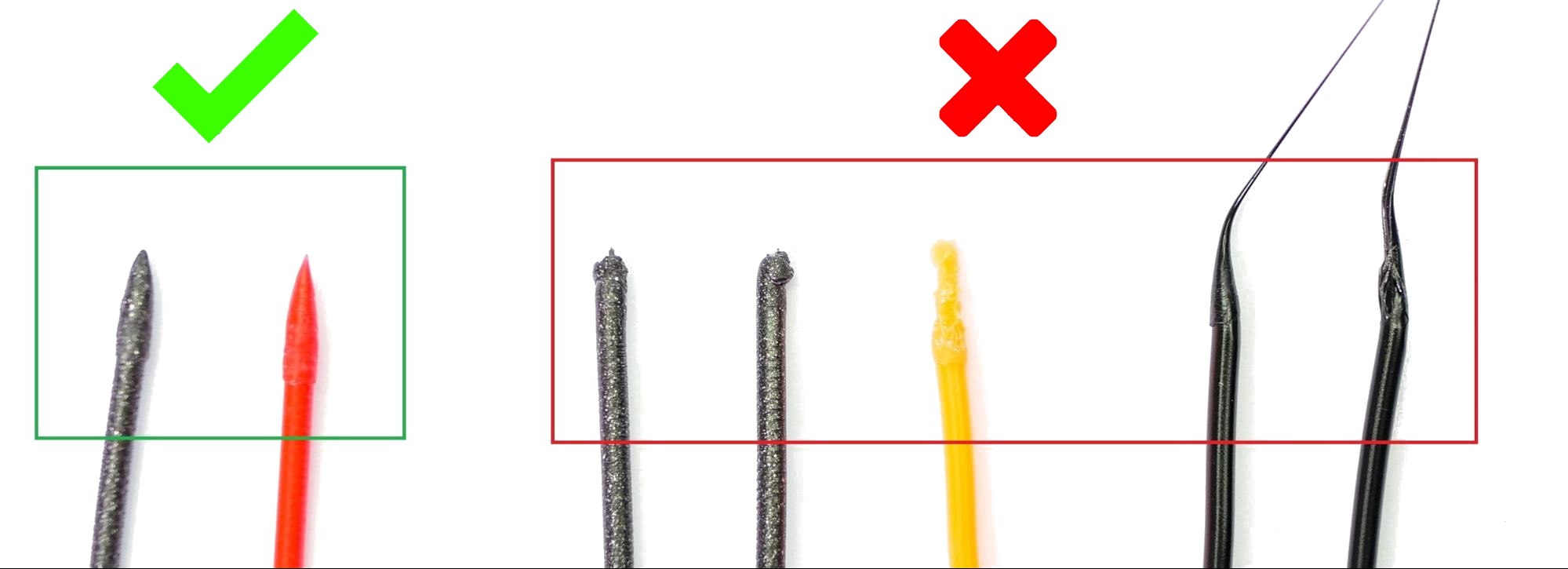

MMU – Filament tips matter!

Experiencing MMU loading errors? Looking at the wrong kind of tips? Great news! I’ve seen into the future and a solution is just around the corner.

My Thingiverse experience

Today I thought I’d talk about the Thingiverse environment and the community as I’ve experienced it, so far. My Thingiverse experience started with sharing my…

My first Thingiverse Publication

I couldn’t wait for the Filament Buffer to be shipped from Prusa and my effort was rewarded. Today I published my first Thingiverse item, a…

Considering a Silicone Heated Pad? Do it!

Two days ago I dealt with heat bed failures where I talked about ordering a silicone heated pad. It arrived yesterday and today I am…

Ender3 – Yet another printer

It seems one printer isn’t enough, but why buy another printer? First, the technology is changing fast. Second, they are cheap. Third, it is a…