Tag: 3d printing

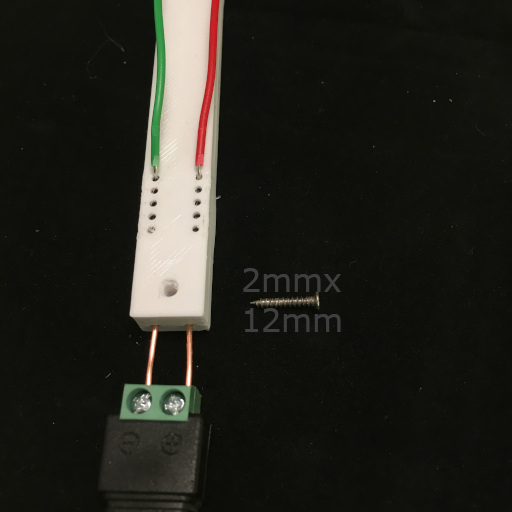

Power Track

The Power Track demonstrates how to provide breadboard style connection points in a print.

February 25, 2020

LED Track Lights

I created LED track lights for a doll house but they can be mounted anywhere.

February 25, 2020

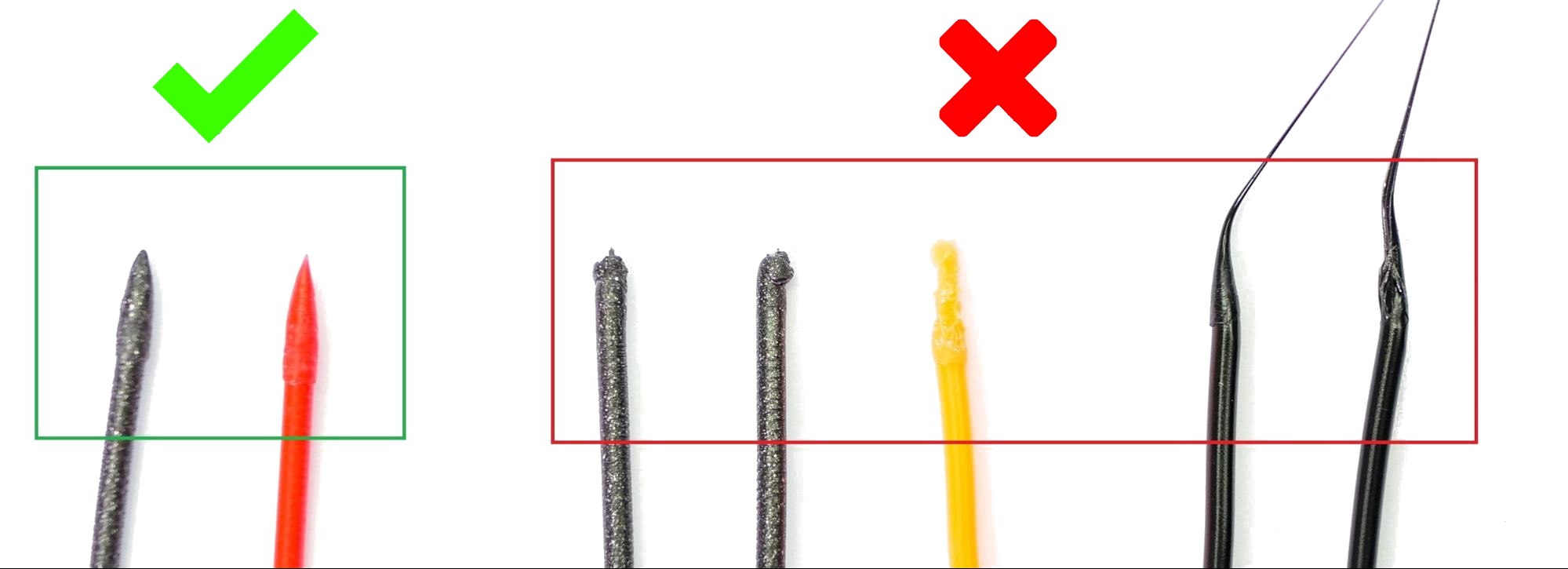

MMU – Filament tips matter!

Experiencing MMU loading errors? Looking at the wrong kind of tips? Great news! I’ve seen into the future and a solution is just around the corner.

August 26, 2019

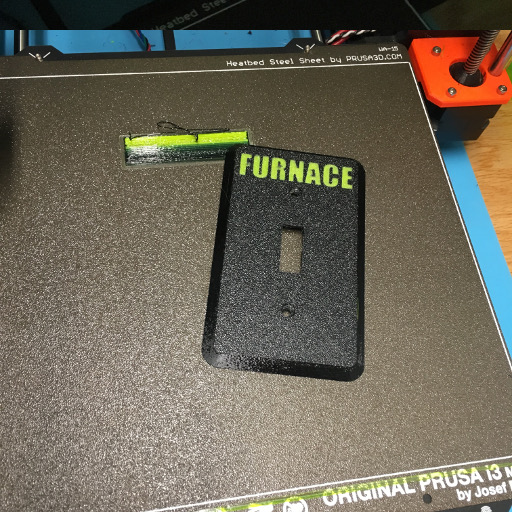

Labeled Switch Plates

A light switch plate covers with UV reflective and glow filaments. Great for a workshop or switch panel.

July 8, 2019

Considering a Silicone Heated Pad? Do it!

Two days ago I dealt with heat bed failures where I talked about ordering a silicone heated pad. It arrived yesterday and today I am…

March 23, 2019

Prusa MK3 – Pi Zero W (NOT)

With my Prusa MK3 up and running I was ready to install the Pi-Zero W I had prepared. I didn’t want the Zero installed until…

March 30, 2018