Two days ago I dealt with heat bed failures where I talked about ordering a silicone heated pad. It arrived yesterday and today I am up and running. It is absolutely great!

What a Difference

One of the most annoying aspects of starting a print job is waiting for the heated bed to make it to temperature. With the silicone heated pad the bed reaches 85 C before the hot end is up to temperature (240 C).

The Silicone Heated Pad

The FLSun Cube does in fact uses the same heated bed size as the Creality 10 so this silicone pad was a perfect fit. I removed the wires and sucked off the solder from the original bed and then cleaned the back surface with rubbing alcohol before applying the pad. The hardest part was removing the solder.

The Wiring

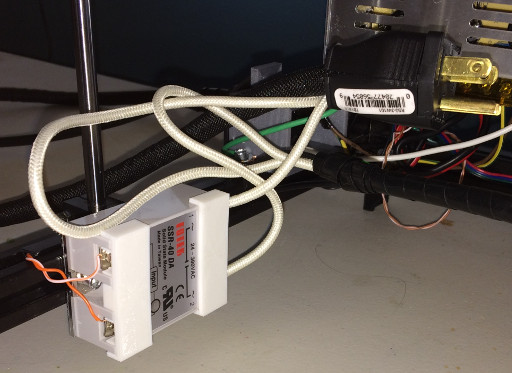

The silicone pad has very long electrical leads of a flexible 10 or 12 G wire. I simply added cable wrap and a male plug. The Solid State Relay (SSR) is the on/off switch for the silicone heated pad. The pad will remain off until the signal line is pulled high to turn it on.

The wire on the silicone pad is very flexible and heavy duty, a lot higher quality than most cords. This was an unexpected upgrade.

Configuration change

The Thermistor is 100K “3950” (Marlin Type 11). A thermistor attached to the pad is not as ideal as one embedded in the build plate but I did check it out and it seemed to be within 5 C. I want to research PID tuning the bed but I will leave that for another day.

Summary

My first print is completed and was better than I have ever from that printer. I feel a lot more comfortable knowing the load from that heated bed is no longer flowing through the control board and whats more I didn’t have to replace the controller.

The Solid State Relay generates no noticeable heat with the heated bed at 85 C. The wire to the bed remains cool even though the bed is now up to temperature before the nozzle. I’d say this was a success!